moviniti sequence

The cloud software for sequencing in production logistics

We are the experts in Just-in-Sequence (JIS) delivery! Our software solution supports logistics service providers (3PL), suppliers (4PL) and manufacturers that need goods synchronized with production – reliable, fully integrable, easy and intuitive to use, and cost-efficient both in terms of basic costs and the costs of functional enhancements.

Key-Features for sequencing

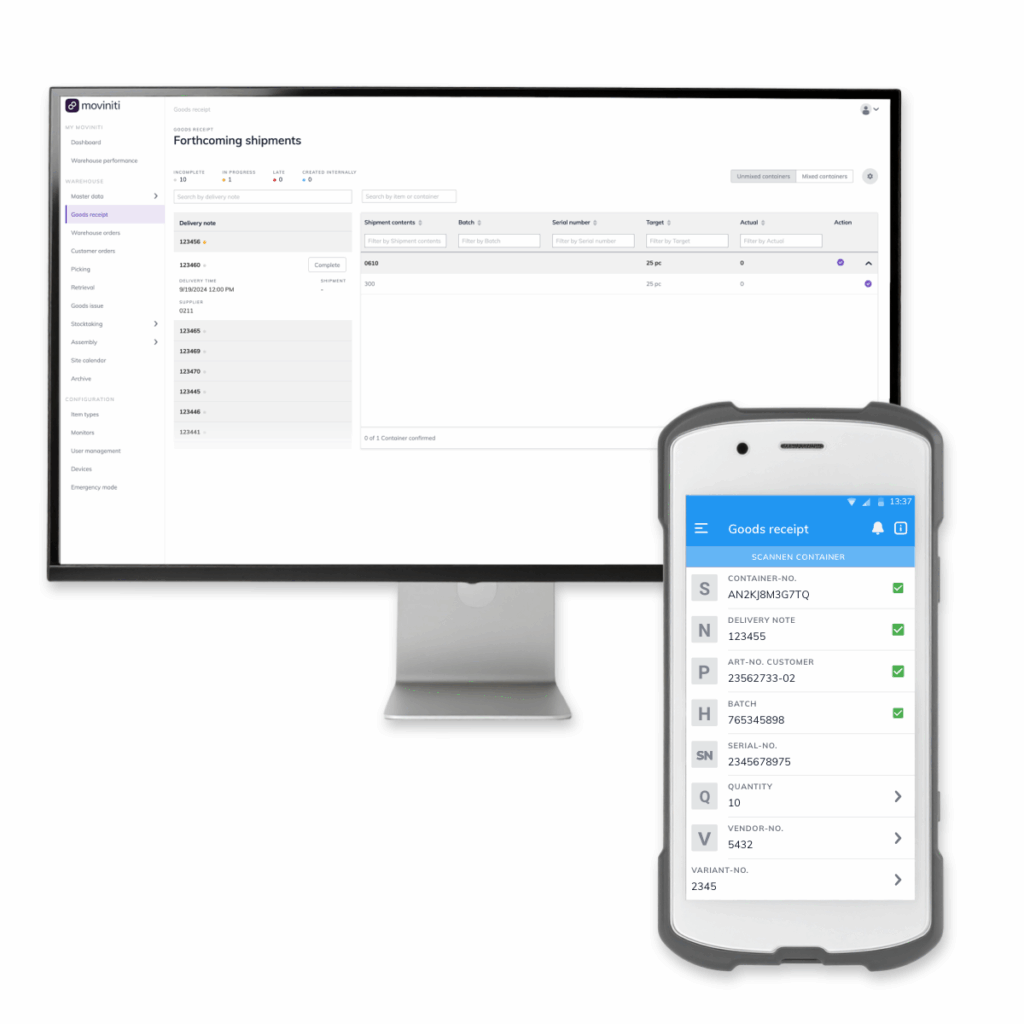

Inbound & Storage

- Receipt of goods according to label standards (e.g., VDA) or supplier-specific labels.

- Electronic delivery notes significantly optimize the inbound process.

- Option to check for outdated indices.

- Additional scanning of delivery documents from SAP possible.

- Optional 100% quality inspection upon receipt.

- Storage based on best-place strategy, custom logic, or closest to the pick location.

- Direct storage on sequencing location.

- Special configuration for block storage possible (lane changes by FIFO, single-type storage).

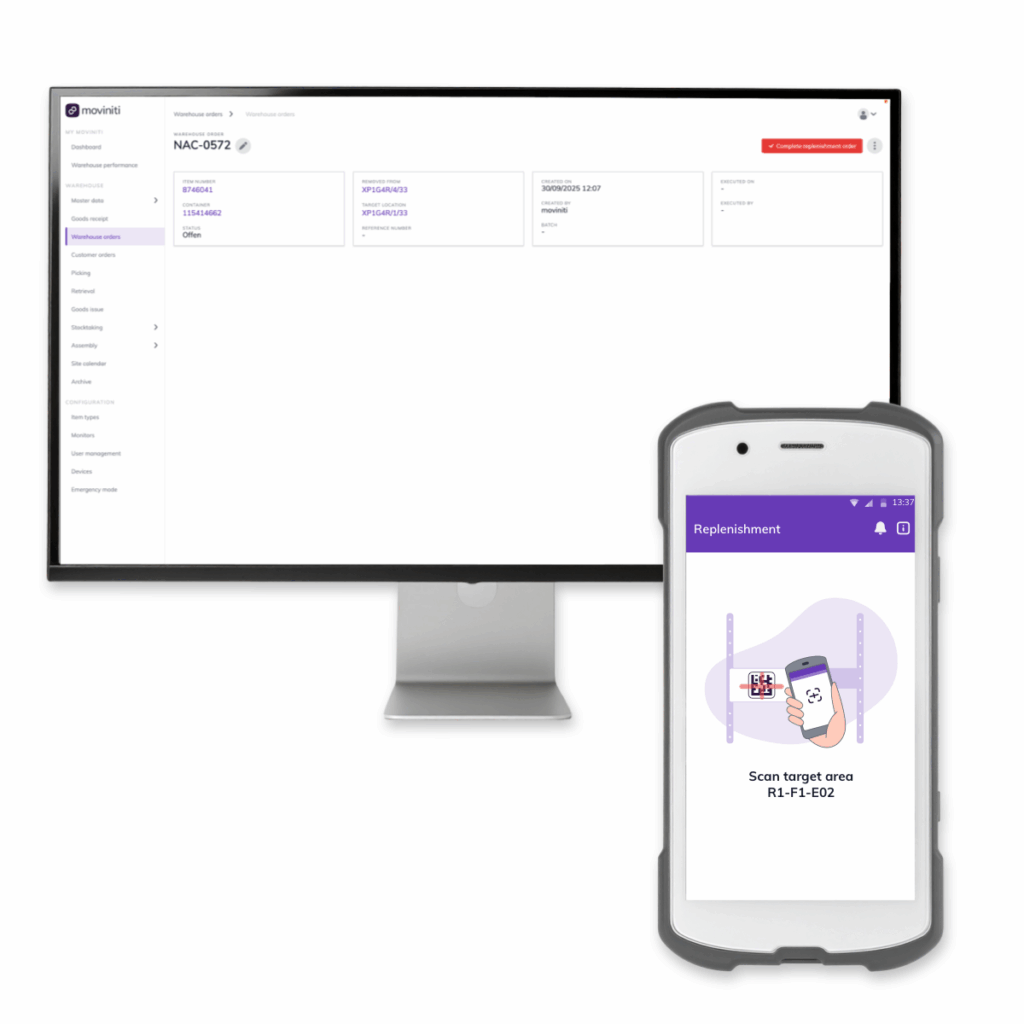

Sequencing

- Easy configuration of production data processing and sequencing via the web application.

- Different strategies for picking order (in sequence, reverse sequence, route-optimized).

- Configuration of scan validations (location scan, serial number, etc.).

- Configuration of sequence lists and sequence labels.

- Picking from single-type containers or racks with plan sequence/pre-sequence.

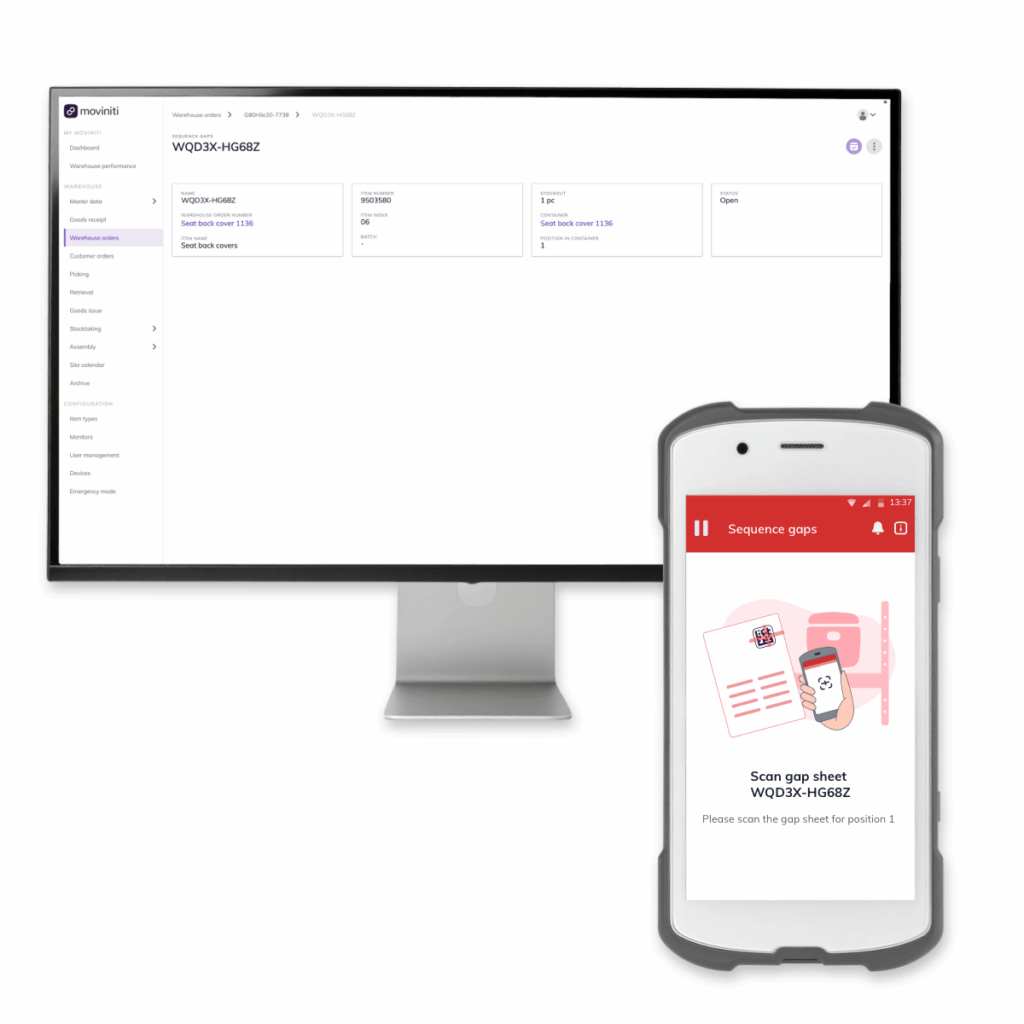

Filling order gaps

- Optional process for refilling items in the sequence container that were not available during sequencing.

- Target area of the sequence order automatically changes to a separate storage area.

- Guided scanner process ensures correct replacement with the right item.

- Automatic transfer to outbound after filling is completed.

Success Stories of our Just-In-Sequence customers

Digitization of manual sequence processes in France

- ⚙️ JIS without WMS, ⏱️ 50 min lead time, 📍 OEM France, 🚀 transparency, 🚘 Automotive

Implementation with complex IT requirements in 6 months

- ⚙️ Assembly and JIS, ⏱️ 45 min lead time, 🔗 9 interfaces, 🚘 Automotive

20% more efficient sequencing processes for 12 part families

- ⚙️ JIS & JIT, 📍 OEM Munich, 🔩 12 part families, 🚀 efficiency, 🚘 Automotive

Why moviniti sequence

Simple yet effective: intuitive operation, reliable quality, and cost-efficient.

Expertise

Developed and tested with the logistics, deep knowledge of JIS supply requirements, high satisfaction in customer support

Intuitive and reliable

Fast onboarding, minimal training, high stability in live operations and extensive validations to ensure to correct sequence order

Future-proof

Quick implementation of change requests, cloud architecture & cybersecurity at the highest standards

Cost-efficient

Pay-per-use monthly fees, unlimited users, automatic server scaling, continuous feature updates

Why moviniti sequence

Simple yet effective: intuitive operation, reliable quality, and cost-efficient.

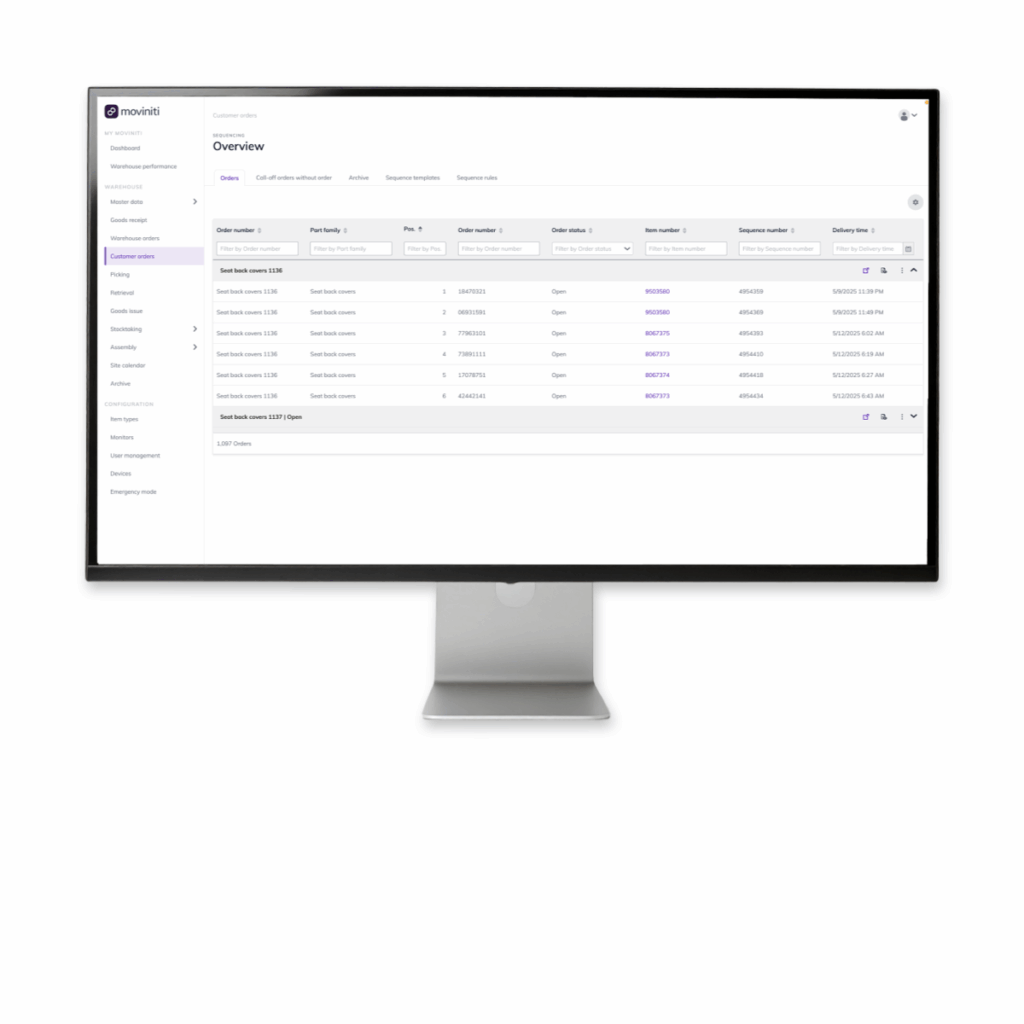

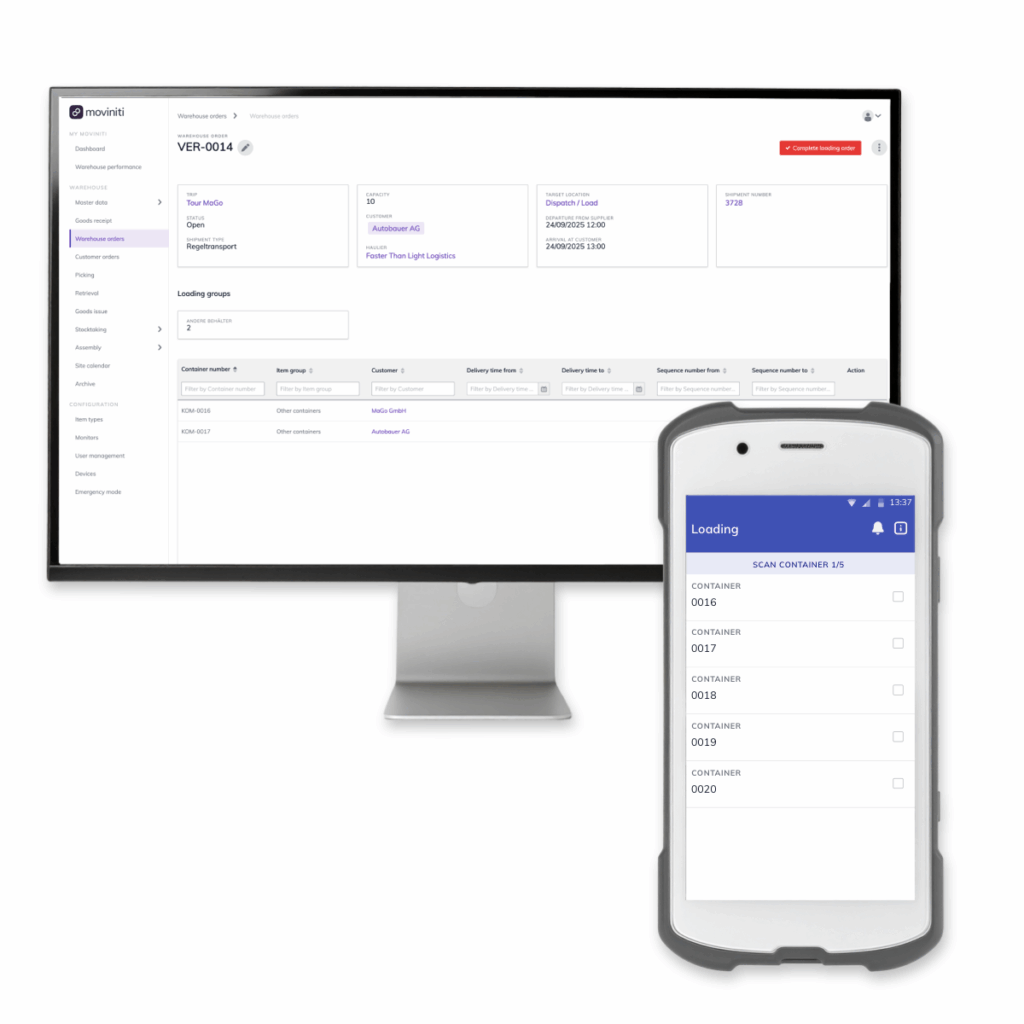

Secure processing of sequence orders

with the mobile Scanner App

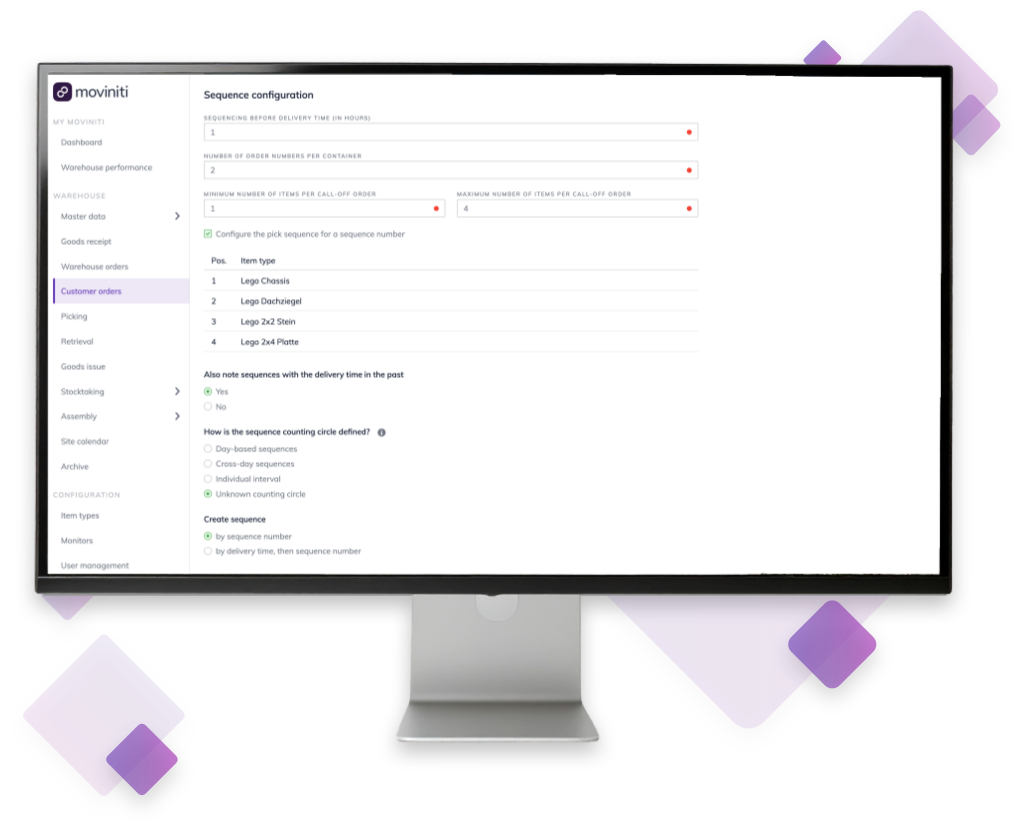

Transparent and simple configuration

with the webapplication

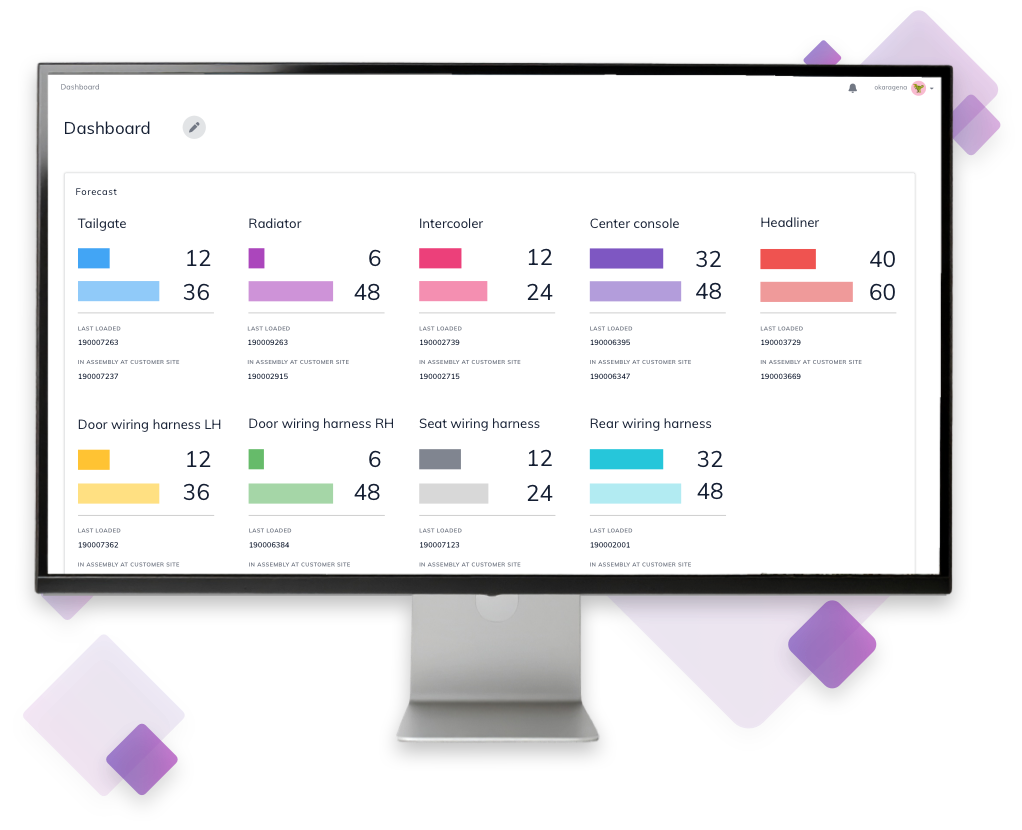

Lead time in real time

Keep track of the current lead time for production with the help of the dashboard

Easy configuration of sequencing areas

Number of orders per sequence rack and sequence strategy can be easily configured via web interface

Implementation process

Tight project deadlines & high demands on secure processes

New moviniti tenants can be set up in the cloud within days, with system access immediately available. Interface integration is typically completed within a few days as well. Total implementation time depends on the clarity of specifications and defined processes.

Our approach: First define the minimum requirements for the processes and then specify the data exchange.

Preparation & Configuration (1–2 weeks)

Setting up the moviniti client, preliminary configuration of the system and processes, entering master data, and setting up a test system. Labeling of storage areas can be started in parallel with the other tasks.

Specification of Interfaces & Processes (2–4 weeks)

Based on the data exchange specification (e.g., according to VDA, Odette, EANCOM or individual interfaces), a mapping to the moviniti standard format is created and the process requirements are defined.

Implementation & Testing (2–3 weeks)

Configurations are finalized in the system and validated in subsequent tests in a real environment (in the warehouse or with the help of our demo warehouse) – including new functions or process steps.

Go-Live & Hypercare (1 week)

After successful acceptance, the web system and scanners are configured. In addition, warehouse staff are trained and inventory data is recorded. The duration of intensive support during the hypercare phase is determined jointly.

Preparation & Configuration (1–2 weeks)

Setting up the moviniti client, preliminary configuration of the system and processes, entering master data, and setting up a test system. Labeling of storage areas can be started in parallel with the other tasks.

Specification of Interfaces & Processes (2–4 weeks)

Based on the data exchange specification (e.g., according to VDA, Odette, EANCOM or individual interfaces), a mapping to the moviniti standard format is created and the process requirements are defined.

Implementation & Testing (2–3 weeks)

Configurations are finalized in the system and validated in subsequent tests in a real environment (in the warehouse or with the help of our demo warehouse) – including new functions or process steps.

Go-Live & Hypercare (1 week)

After successful acceptance, the web system and scanners are configured. In addition, warehouse staff are trained and inventory data is recorded. The duration of intensive support during the hypercare phase is determined jointly.

Low start-up costs & licenses

One-time implementation costs, monthly cloud licenses scaled by warehouse volume, optional support packages.

One-time implementation costs

Implementation costs vary by project size. On average, moviniti is about 10% cheaper than comparable products due to modular setup and simple integration. Costs are incurred for:

- Project management & kick-off

- Specification of interfaces and processes

- Development of API adapters and additional features

- Training of users & key users

- Acceptance/integration tests

- Individually agreed hypercare support after go-live

depending on project

one-time

Pay-by-Use monthly license

The monthly license fees are scaled fairly according to the pay-per-use principle based on the warehouse volume (goods receipts & picks in sequencing). The cloud license includes the following:

- Basic WMS functions and sequencing

- Unlimited server performance

- Automatic scaling & maintenance

- Continuous updates of moviniti with new features

- Technical maintenance of the code base & infrastructure

- Support during business hours

775 € + graduated price per pick

per month

Exemplary scenarios

Three cost examples show realistic scenarios with different volumes and different support options.

Low volume & 1-shift support

Support package: Essential

Goods receipt: 1,000 per month

Picks: 7,500 per month

1,207 €

per month

High volume & 2-shift support

Support package: Professional

Goods receipt: 2,000 per month

Picks: 80,000 per month

4,868€

per month

High volume & 3-shift support

Support package: Enterprise

Goods receipt: 6,000 per month

Picks: 200,000 per month

11,138 €

per month

Let's calculate your price!

moviniti adapts flexibly to your needs – an initial cost estimate is easy to obtain.